Applications

Mainly used for high-reliability & void-free soldering between high-power chips and substrates such as packaging of semiconductor lasers, RFIC/MMIC and power devices, optimizing soldering quality with vacuum, inert, and reducing atmospheres.

Features

Rapid and precise temperature control (±0.5℃)

Excellent solder joint quality with void rate below 2%

Exceptional temperature uniformity (±1.5%)

Formic acid process for low-temperature solders

Precise process gas flow control

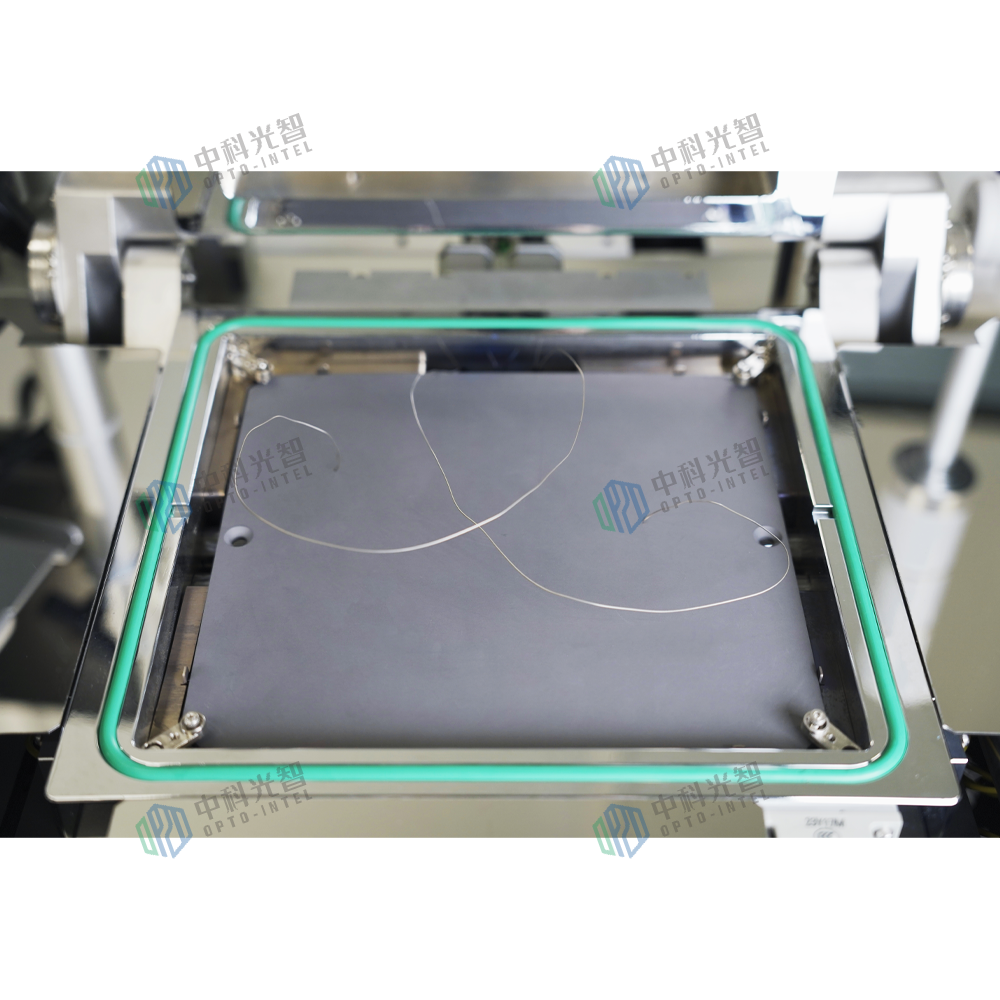

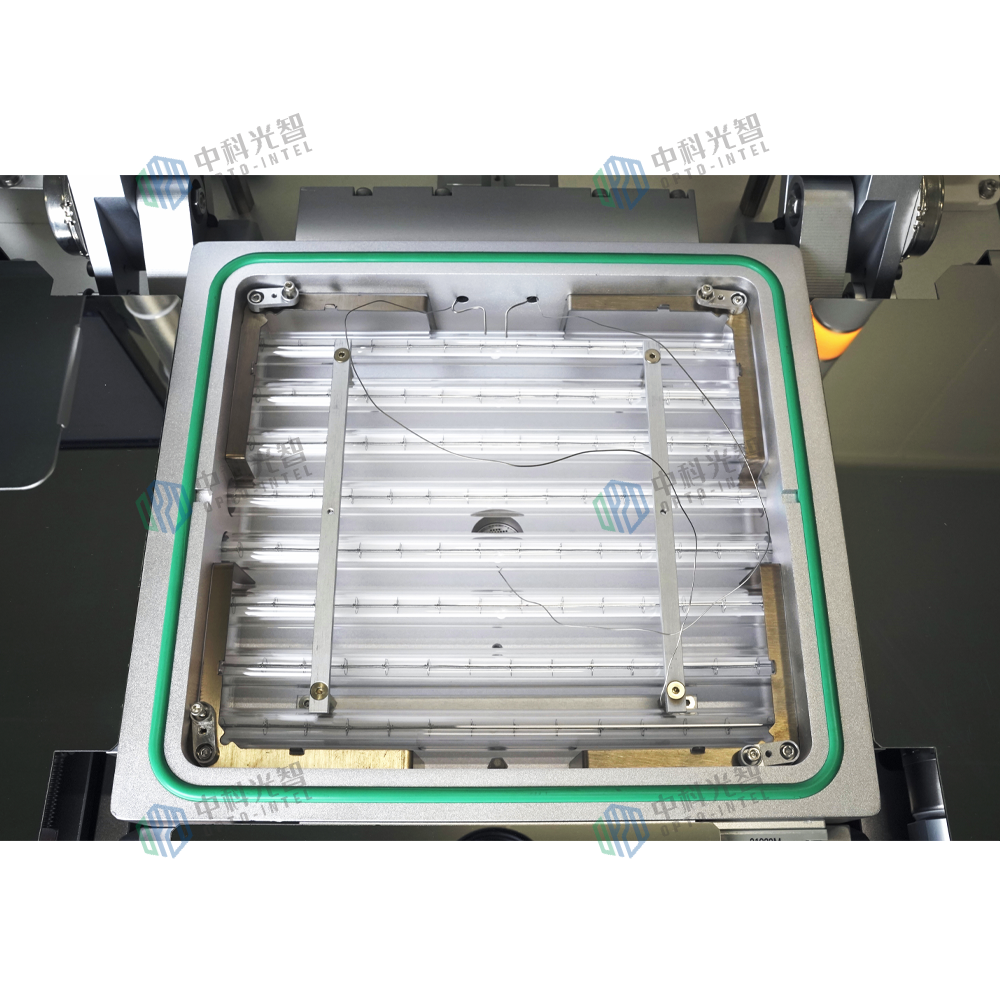

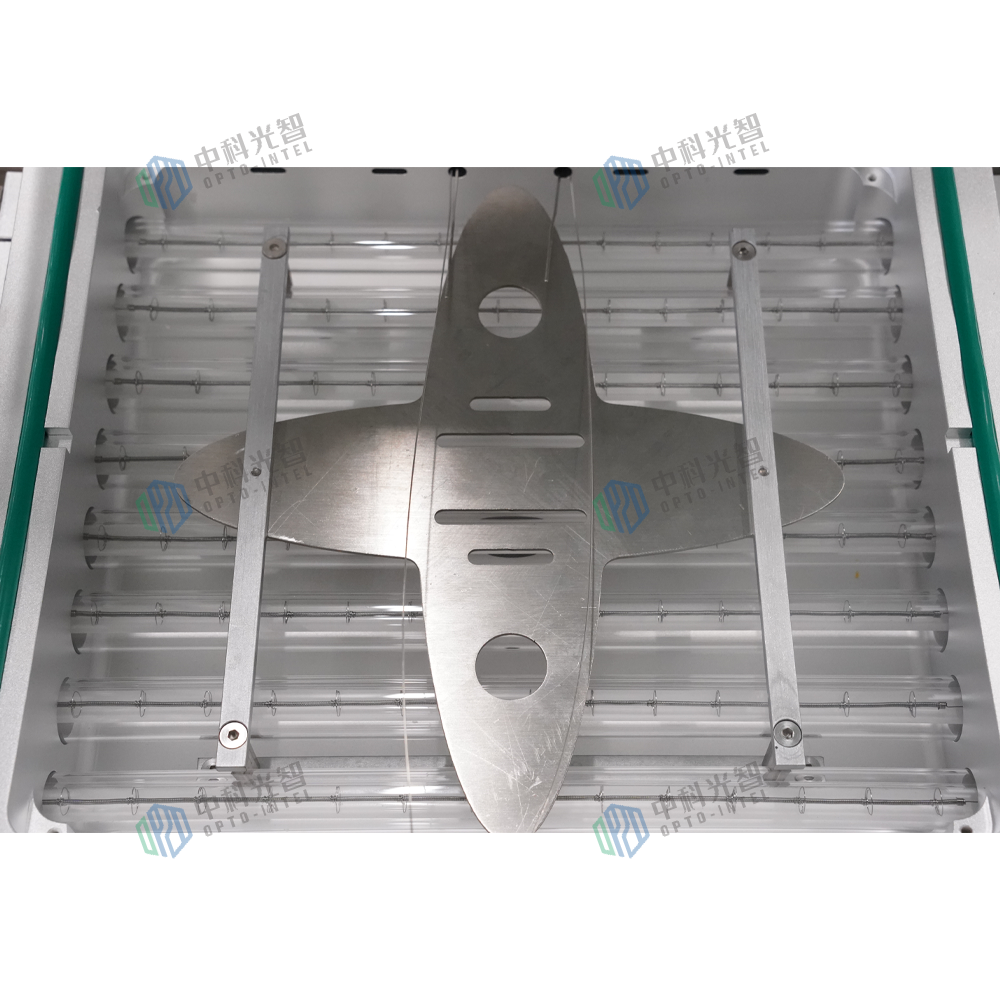

Custom direct-heated tooling fixture

Simple and intuitive GUI

Specifications

Heating Plate | 290mm×350mm×6mm |

Clearance over Heating Plate | 100mm |

Process Temperature | Max 450℃ |

Heating Accuracy | Better than ±0.5℃ |

Heating Uniformity | Better than ±2% (with 20mm edge exclusion) |

Heating Rate | 3℃/s |

Cooling Rate | 0.85℃/s |

Gas Channels | MFC control with solenoid valve |

Chamber Vacuum | 0.05mbar based on dry pump, measured by Pirani gauge |

Control System | PLC control system with Windows-based IPC, supporting MES |

Options | Flux process, overpressure process, top heating, barcode scanner |

Power Supply | AC380V, 50/60Hz, 16kW |